Get a Detailed Quote Now!

Contact our Custom Injection Molding Manager today for a consultation!

At Burger & Brown Engineering, we are troubleshooters. We have experience running molds and analyzing molding parameters for difficult parts. Our RJG Certified Master Molders and Scientific Coolingsm Specialists focus on solutions to produce parts that perform as expected.

Repeatable All-Electric Presses from 50 to 220 Tonnes

Mold Tryouts

Short Run

Production Quantities

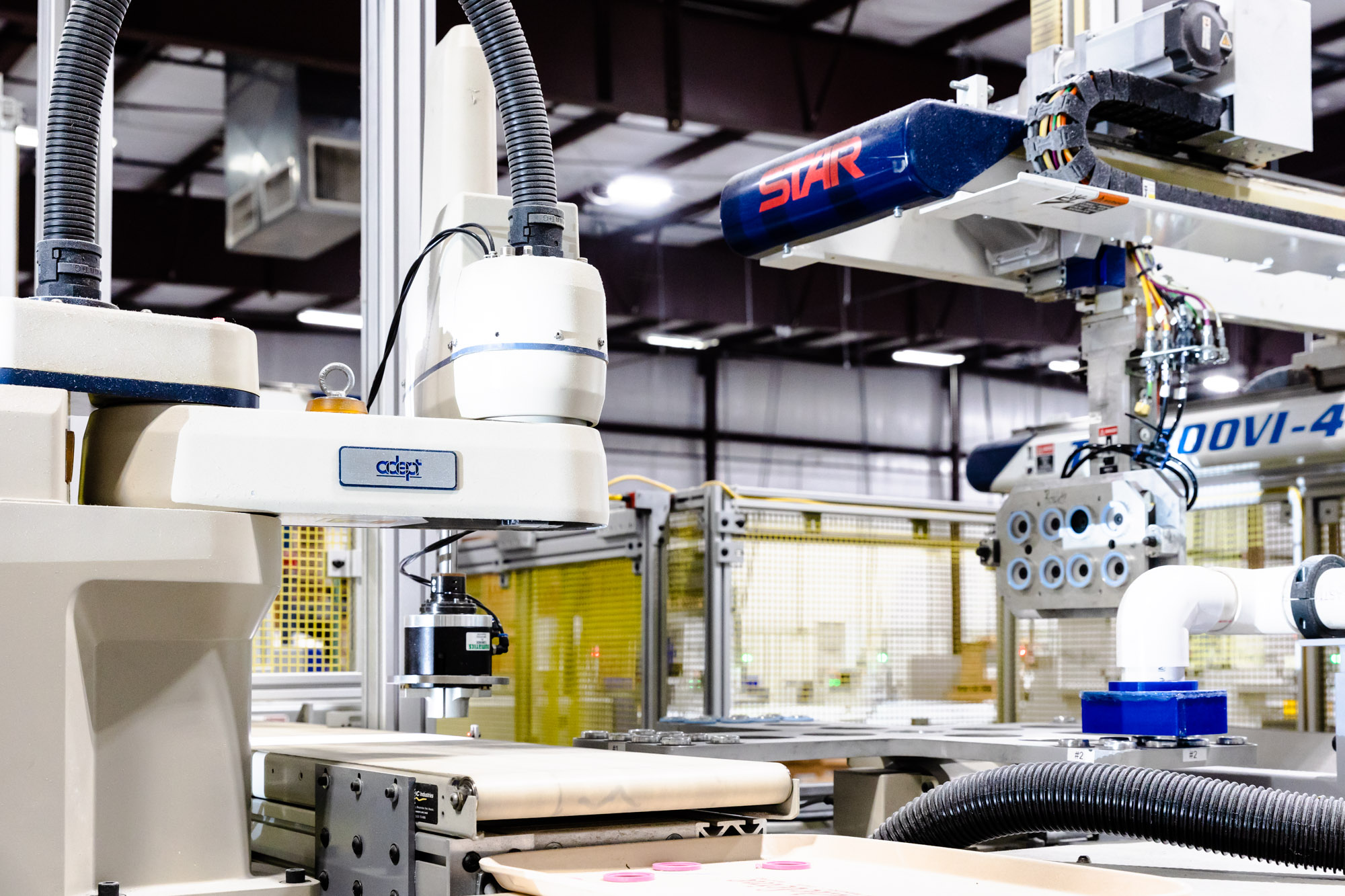

Robotic Assistance

Resins Molded:

|

|

|

|

|

|

|

|

|

|

|

|

|

We talk with you to understand the most important features of your injection molded parts. We use a scientific approach using data and experimentation if needed to pinpoint the process variables that will produce your desired end result.

From mold tryout to capacity production, your satisfaction is our goal.

We are experts

We have a focused Injection Molding Department with staff experienced in molding a variety of materials.

We're constantly learning

We work closely with area suppliers of machinery and resins and are always learning about new materials and technologies.

We are hands-on

Our staff monitors production constantly to ensure best practices in cooling water efficiency and energy usage.

Shot size of our injection molding machines is from 3 to 399 grams.

Yes, we have robotic capabilities that allow us to run two-color parts.

We offer component assembly such as heat staking. Machining completed parts is also available.