Highlights

- Our engineers work together as a team with each manufacturing department: Industrial Automation, Precision CNC Machining, High Speed Micro Milling, CNC Swiss Turning, Custom Injection Molding, Industrial Automation, and Quality Assurance.

- There’s always an engineer available to consult with machinists and Quality Assurance if a difficulty arises in a customer part.

- Engineering provides detailed assembly drawings as needed to complete product and process documentation.

- Prototypes are produced as required by the project requirements. In-house Additive Manufacturing or 3D Printing may be used in addition to Manual or CNC Machining to produce prototypes depending on cost and time constraints.

Our Process

Consultation is the first step to successful project completion. During the consultation, we define the scope of the project and document each step. We create a timeline and milestones. Customers are welcome to check in along the way to monitor progress and stay informed. Meetings may take place at our facility in Grandview, Missouri or at the customer’s site depending on the scope of work to be done.

Why Us?

Efficient

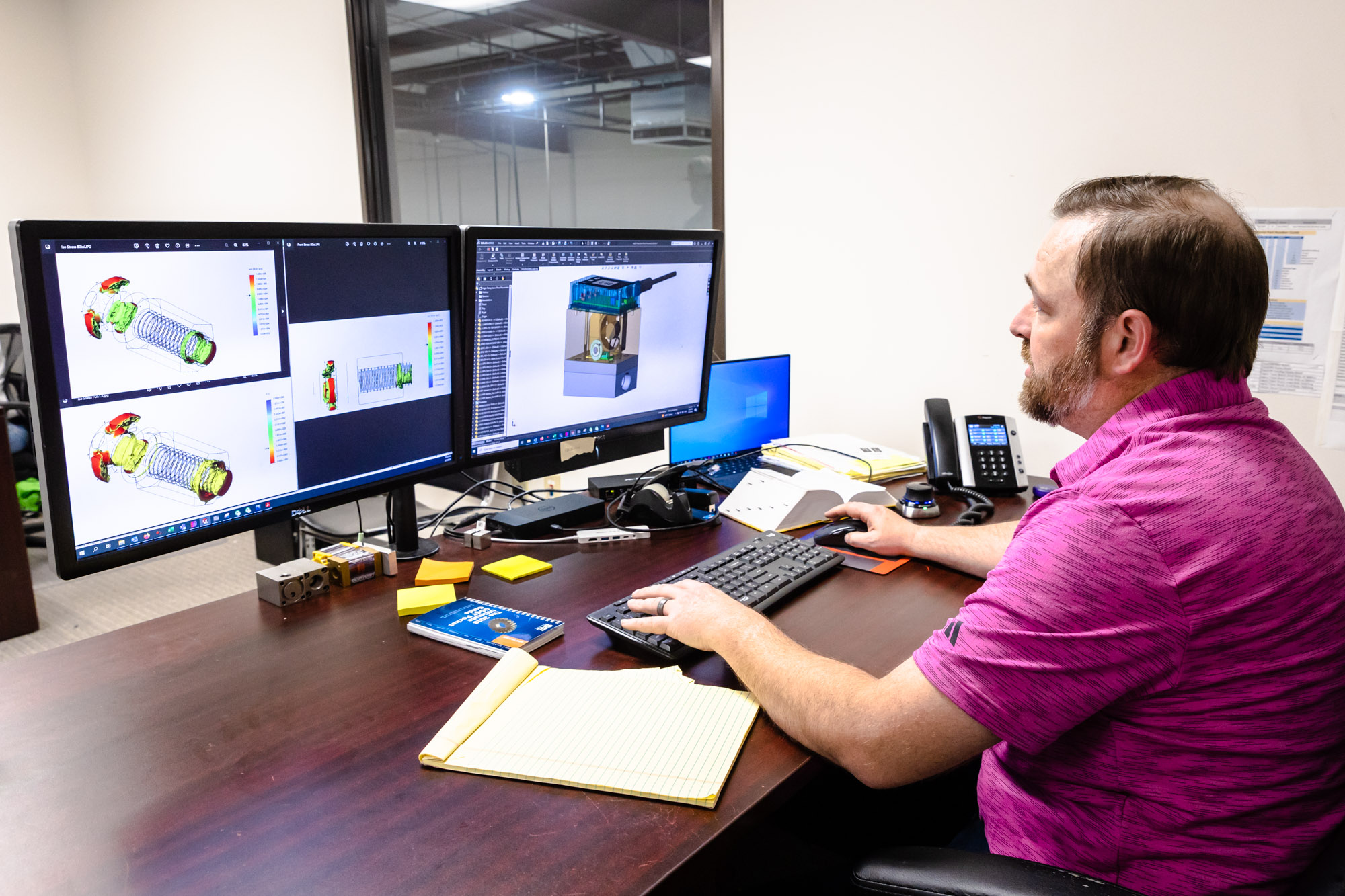

An Engineering review can solve problems with part design before manufacturing is done, saving money and time.

Assured

Prototype parts provided by engineering and manufacturing can test the form, fit, and function of an assembly component or change before finalization.

Insightful

Drawings and documentation provided by our staff can support our customer's design department and capabilities.

Frequently Asked Questions

We visit customers located within a 200-mile radius of our facility in Grandview, MO.

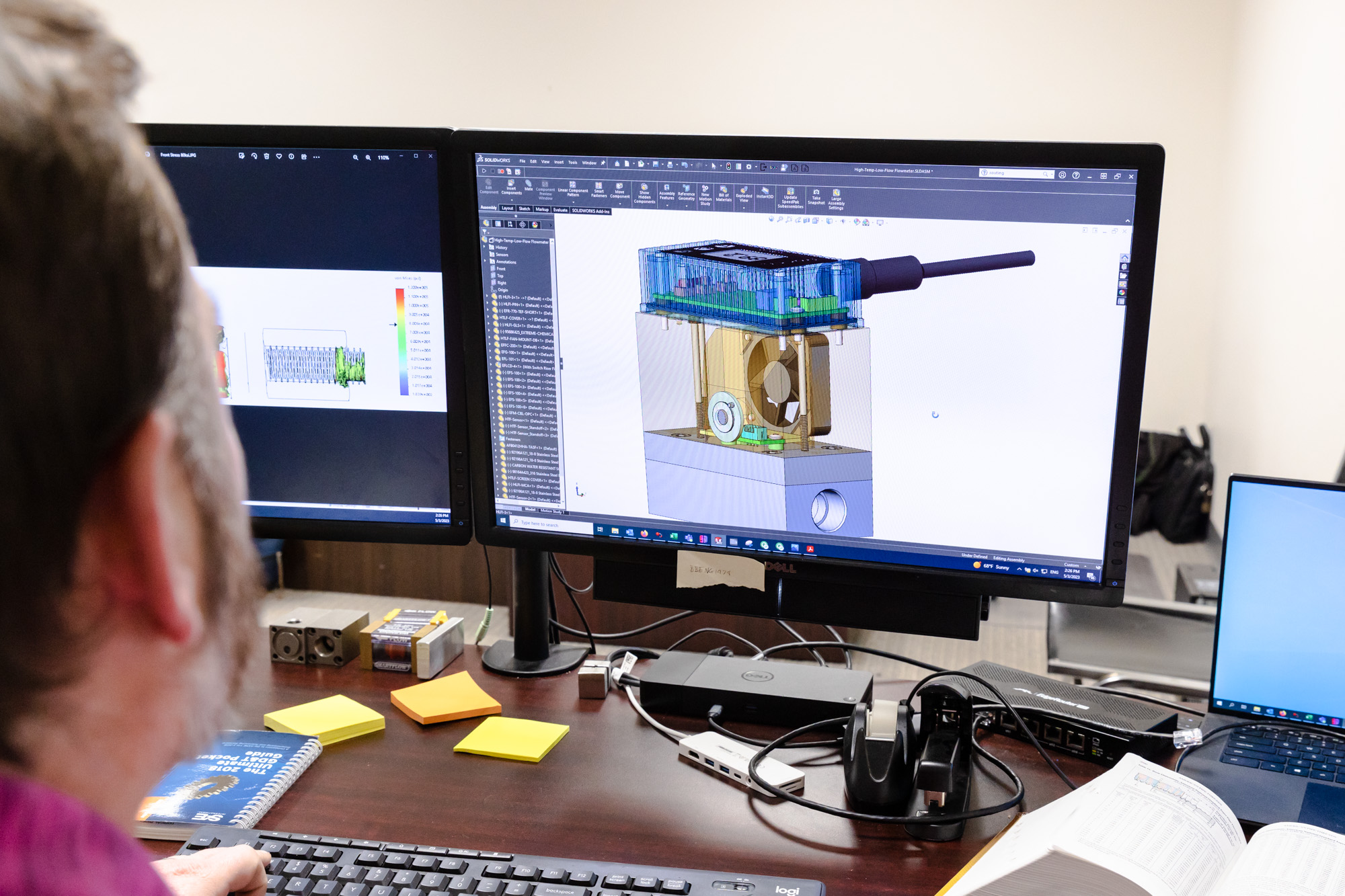

We use Solidworks and can export various 3D file formats.

We are flexible and open to new opportunities in Engineering.