Get a Detailed Quote Now!

Ready for custom micro-machined components? Call us today for a quote!

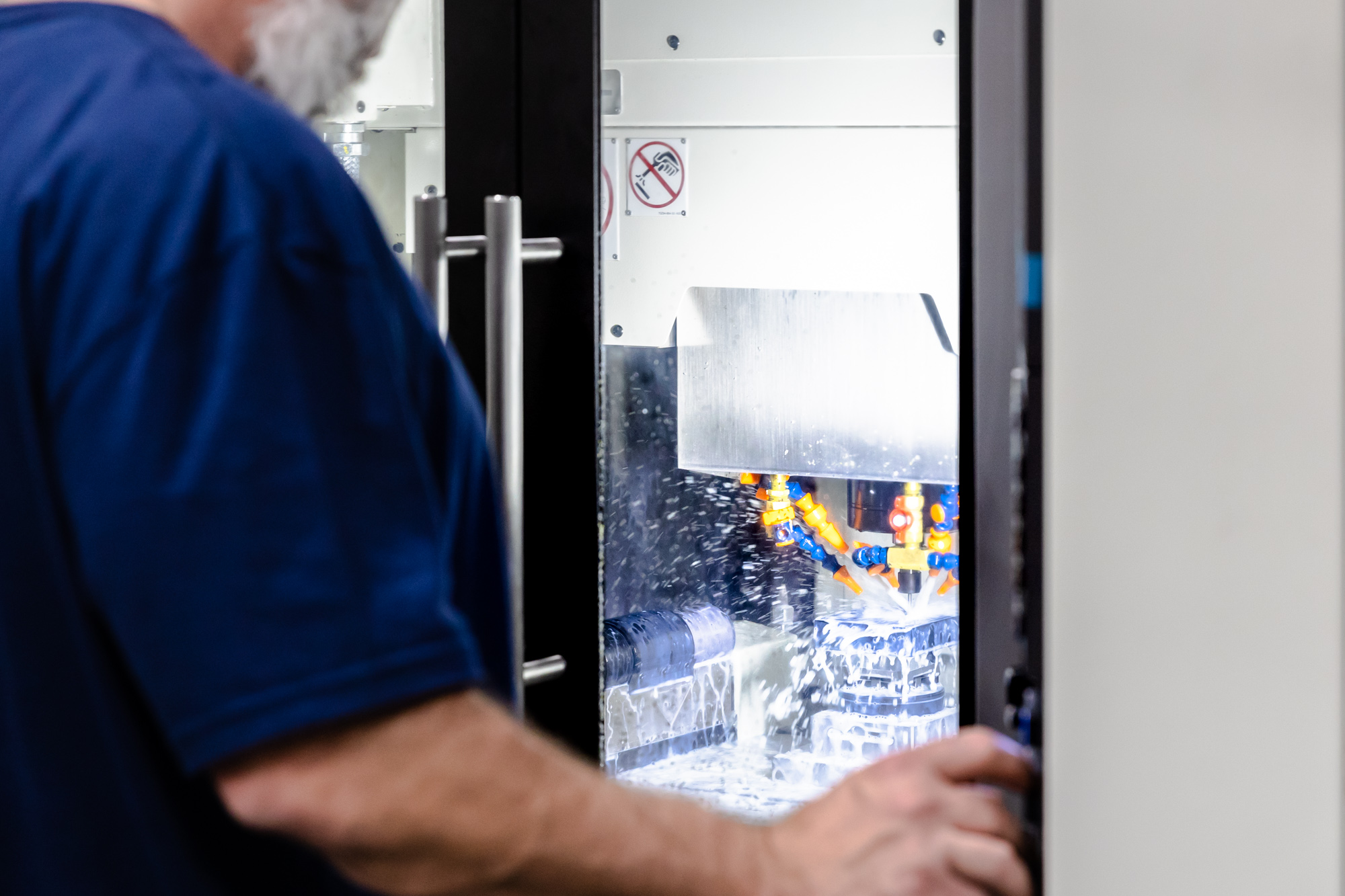

Semiconductor test sockets are made from high-performance materials that are suited for extreme temperature conditions while maintaining size and shape. High Speed Micro Milling uses spindle speeds of up to 60,000RPM to make extremely small diameter holes as small as 0.003″/.076mm in diameter. True position tolerance is held within .001″/.03mm.

Carbon Fiber

Vespel

Torlon

Acetal

PEEK

SEMITRON

Machinable Ceramics

Brass

Copper

Stainless Steel

Titanium

When a quote request is received, our Sales Manager and staff review requirements of each part. We consider material, manufacturing time, quality assurance, and finish requirements during the quoting phase. When schedule and price are agreed upon, our staff enters the work order into the queue and we begin production. We welcome any of your questions along the way for a timely resolution.

Expert staff

Dedicated staff with years of experience in high-speed micro milling ensure strict adherence of finished part to print.

Precise results

Each part is cleaned and processed by hand as needed. Automated cleaning methods can sometimes produce undesirable results. Our Quality Assurance department produces the appropriate inspection reports according to the work instructions.

Yes, Micro-Machining has been used to produce parts for Medical and Luxury Watch applications.

Any intricate part smaller than 12″ square can be manufactured using Micro-Machining.

We have 12 High-Speed Micro-Machining centers.