Service Highlights

Precision CNC Manufacturing includes:

Procurement – raw materials purchased from trusted suppliers

Programming – machine instructions written by veteran machinists

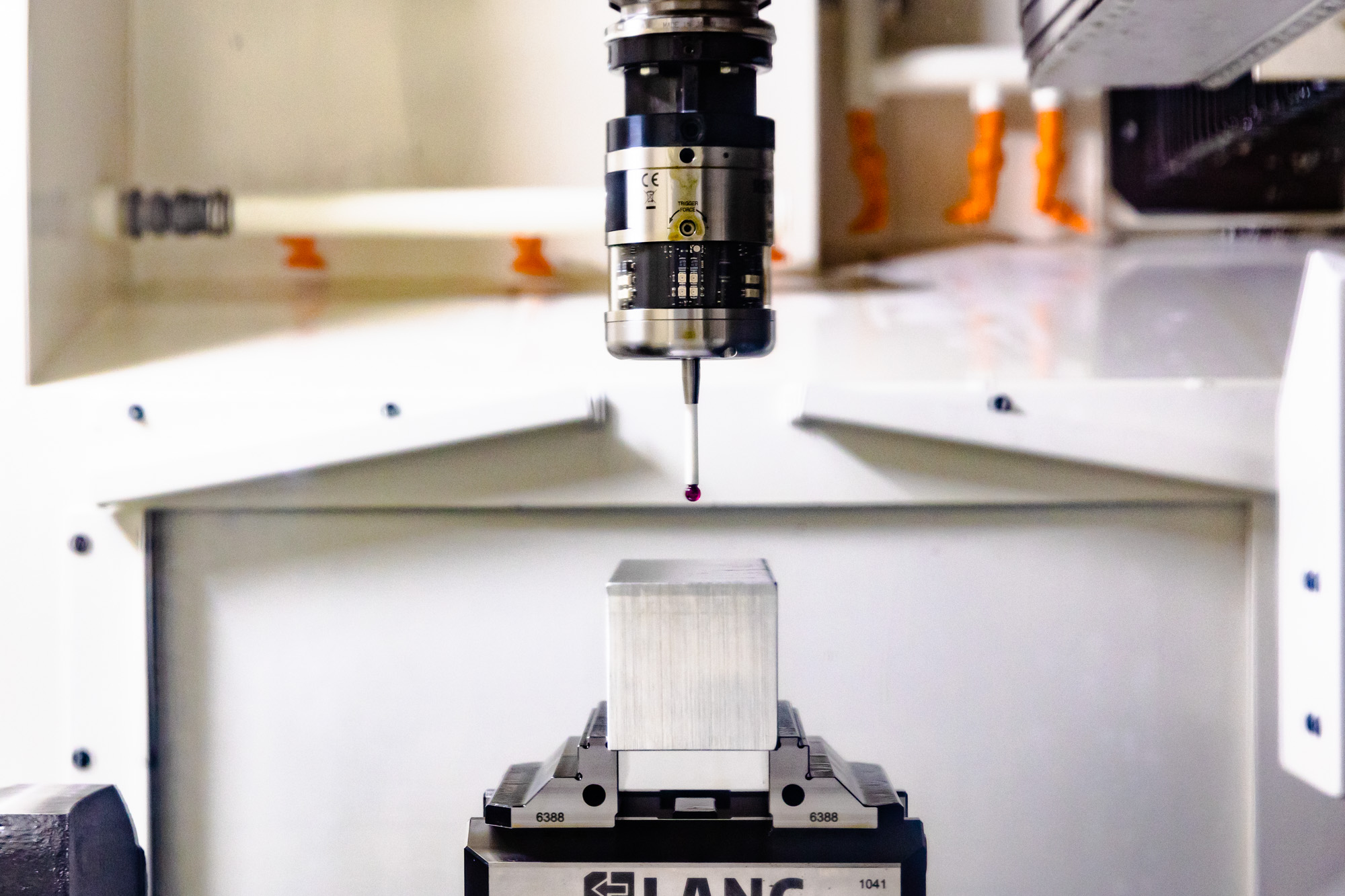

Quality Assurance – inspection and reports written to document condition of finished goods to print

Our Resources:

Engineering resources are available to review and confirm manufacturability as needed. Based on volume, geometry, materials and schedule, we select the perfect machines from our technologies to complete your project.

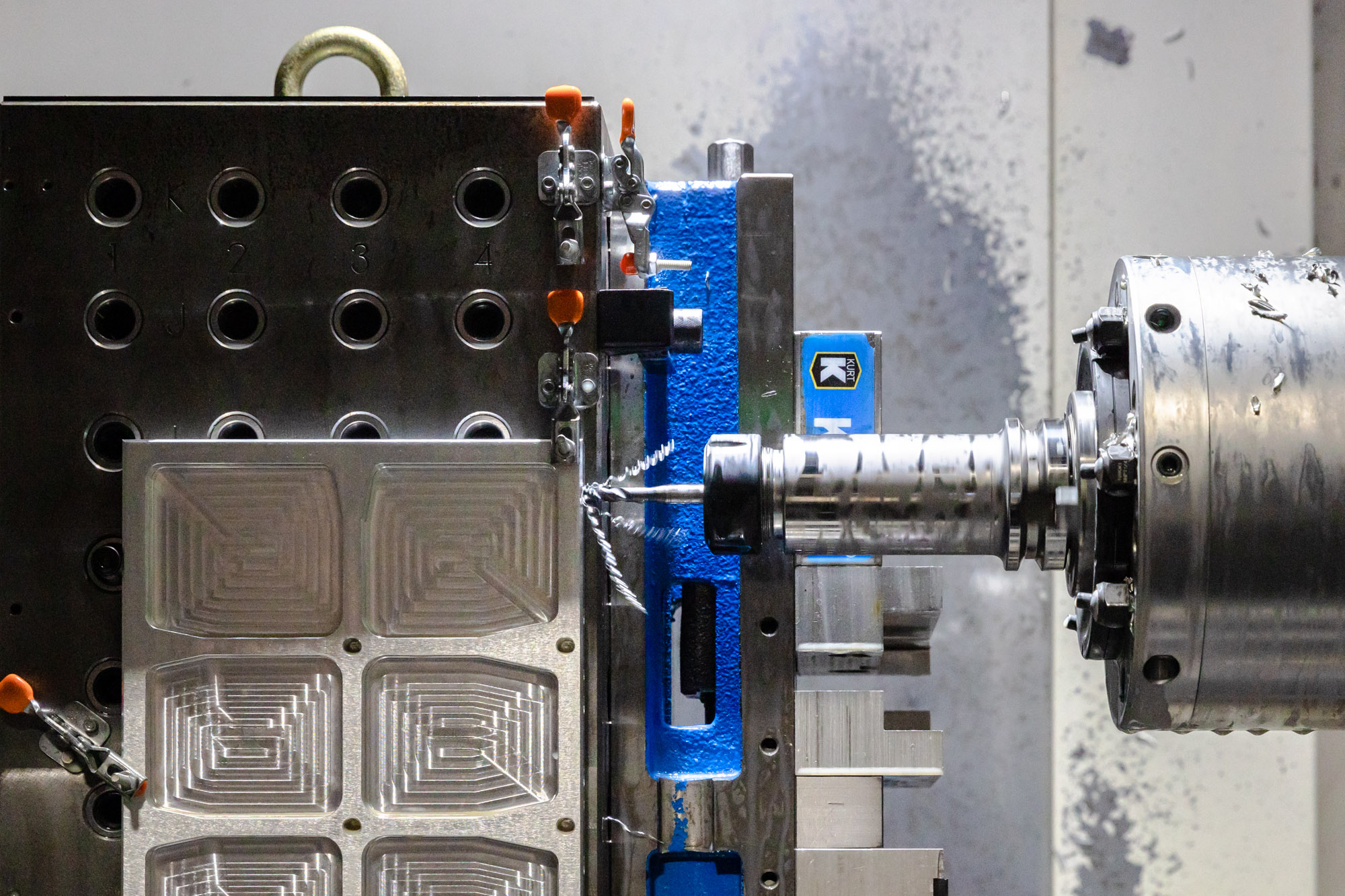

CNC Swiss Lathes

Live Tooling Lathes

3 Axis, 4 Axis, 5 Axis CNC Machines

Horizontal Machining Centers

Our Process

When we receive a quote request, our Sales Manager and team members review requirements of each part, including material, manufacturing time, quality assurance, and finish requirements. Once we come to an agreement regarding scheduling and price, we begin production! We continually communicate with our clients in order to resolve any questions and communicate the timeline clearly.

Why Us?

One-stop shop

The various services within our facility simplify single-source purchasing for our customers.

Easy access

Our location in the heartland means quicker, less expensive transit times for most areas within the continental US.

Experts in the field

Our decades of experience make us the supplier you can trust with your precision manufacturing.

Frequently Asked Questions

The largest CNC milled part we can make is 24″ wide x 34″ long x 10″ thick. The longest part produced by our CNC lathes using a bar feeder is 3″ in diameter x 14″ long. Using a chuck, the maximum length is 18″ on a CNC lathe.

It depends. For one or two parts or prototype quantities, we would recommend using our manual machining department.

We don’t work on personal autos.