Get a Detailed Quote Now!

Send an NDA and drawing along with your delivery needs to our Sales Manager for a consultation.

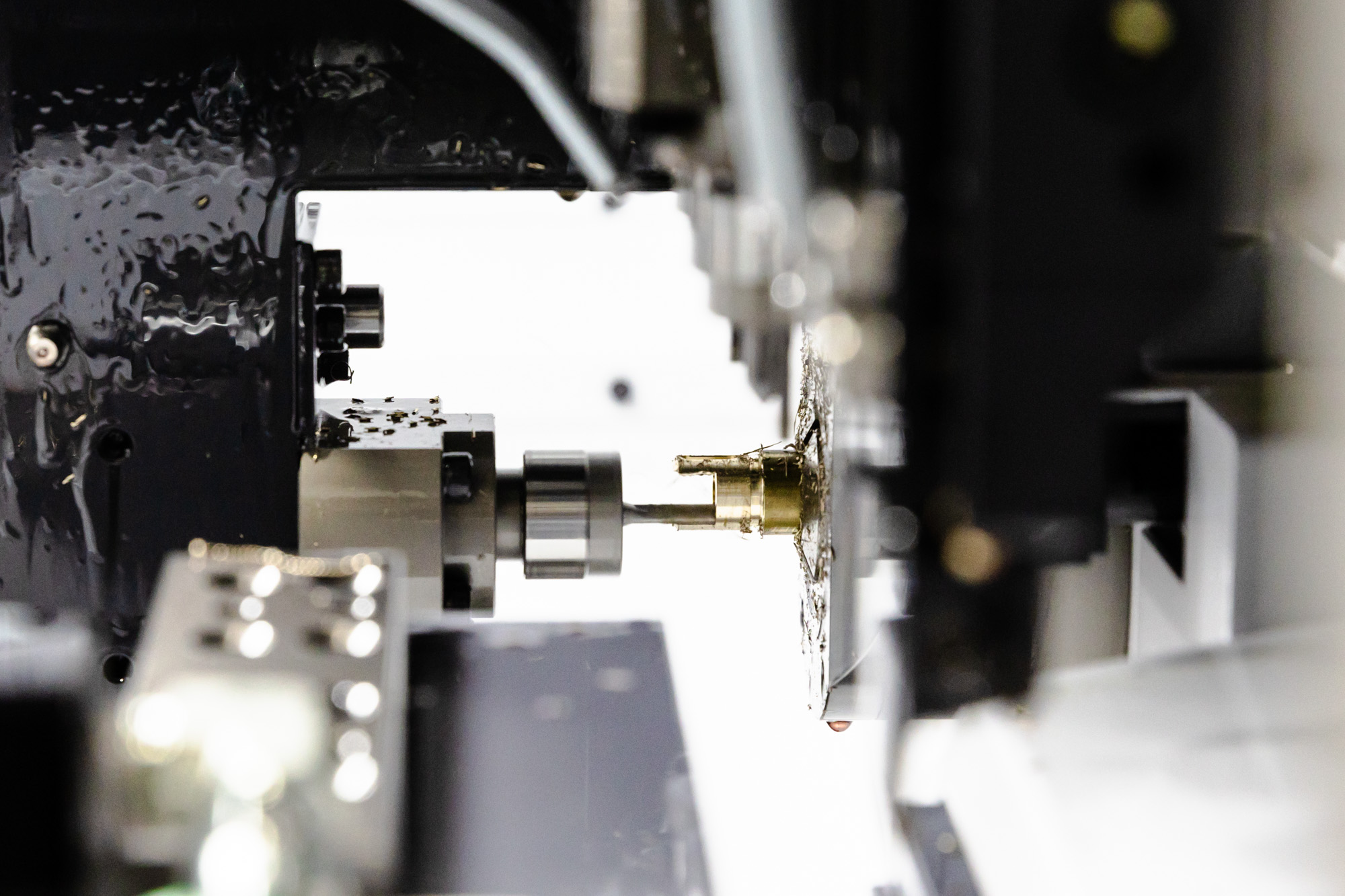

Our Swiss Turning department produces parts between .010" and 0.75" in diameter. A wide variety of materials can be successfully machined using this technology. Plastics are notoriously difficult to machine, but Burger & Brown Engineering successfully processes them using Swiss Turning. Advantages to producing parts on these machines include:

Finer surface finish

Shorter lead times

Higher accuracy and repeatability for long runs

Material flexibility

When a quote request is received, our Sales Manager and staff review requirements of each part. Material, manufacturing time, quality assurance and finish requirements are all taken into consideration during the quoting phase. When schedule and price are agreed upon, our staff enters the work order into the queue and production begins. Any questions along the way are communicated by the sales staff to the customer for timely resolution.

Varied expertise

We have experience with many different materials such as: Performance Plastics, Brass, Stainless Steel, Titanium, Hastelloy, Molybdenum, Haynes L605

Consistency

We utilize Swiss Turning to maintain close tolerances and provide components with high repeatability.

Stability

Our climate-controlled facility helps us maintain dimensional stability in machined parts for successful project outcomes.

3/4″

0.010″

The cutting tool operates very close to the guide bushing that holds the material. This stabilizes the material, reducing movement in the workpiece.

Swiss Lathes can produce more features in a single setup than conventional CNC Lathes due to the number of axes of control. Depending on part features, parts run on conventional CNC Lathes may require additional setups.

Swiss Lathes use oil-based coolant which transfers heat away from the part more efficiently than water-based coolants allowing faster cutting speed.