IC (Integrated Circuit) Chips that provide the computing power for modern electronics may take a year or more of testing and development before production becomes viable. That’s where SGB Tooling’s specialty service supports IC chip manufacturing.

With 28 years of design engineering experience, Sam Glazebrook founded his company in January of 2018 to provide the test fixtures used by US semiconductor manufacturers. Sam designs all the components for the test fixtures, assembles and ships the fixtures to his customers.

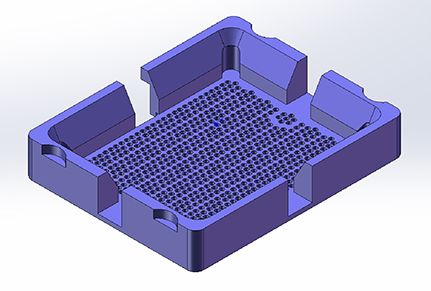

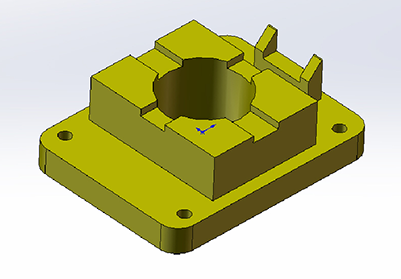

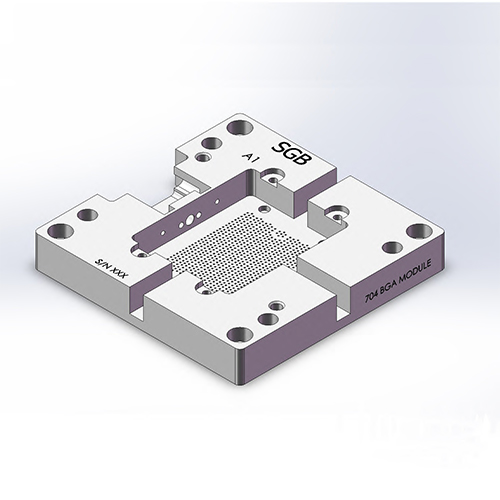

SGB Tooling fixtures enable you to place a single chip inside the fixture pocket without creating a permanent electrical connection for ease of repetitive testing. Hundreds of test points make contact with spring-loaded pins in an extremely tight array.

SGB Test Socket Model

SGB Test Socket Model

A variety of materials are used for these high-tech fixtures including specialty plastics and ceramics that are subject to extreme temperatures during IC Chip testing and production.

Sam is able to compete with large companies because he has complete control over every aspect of development and production costs. He has developed a system for quotations and invoicing that has allowed him to streamline operations.

Sam also knows his customers’ needs and what’s most important to each of them. Flexibility is crucial when working with ever-changing requirements and expectations of a given project. All of SGB Tooling’s customers want their test fixtures to work “right out of the box”.

Using the relationships he has cultivated throughout his career, Sam Glazebrook has created a thriving business in the semiconductor industry that will propel him forward successfully.