There were early signs. When I was 14, I sold Christmas cards to earn money for a 3-speed English bike that I desperately wanted. At age 16, I bought an ice-cream business from my high-school friend. I especially liked this business because I was totally independent, and the outcome depended on my own initiative. It was a summer operation that required a bicycle and a Coleman cooler fastened to a home-made bike trailer. Five pounds of dry ice kept the ice-cream frozen each day. My products were bought wholesale from Wright’s creamery, in my small hometown of Wellington, KS.

Five days a week I took off in the early afternoon with a cooler full of Eskimo pies, fudgesicles, popsicles, ice cream bars, and even drumsticks. My route covered about 8 blocks starting at the Sumner County courthouse on north Washington Ave., the main street of Wellington. The courthouse was a great place for selling. It was a busy place, and I was allowed to bring my ice-cream trailer into the building and make the rounds in various offices. There were many willing customers.

My route then proceeded south on Washington to the Standard Oil filling station. In those days attendants pumped gas, and mechanics worked inside the station doing oil changes and such. Down the main street there were several similar businesses and workers liked taking an ice-cream break on a hot afternoon. The route ended at the southern end of the business district near a Phillips 66 station and the Santa Fe railroad depot. Business was generally good, and I brought home a few dollars each week, Monday through Friday.

I operated the ice-cream business for two seasons and then handed it off to a friend as I left for Navy boot camp in San Diego in late August 1962. Goodbyes were said to family and friends, and I boarded the Santa Fe Special, eagerly anticipating the 2-day trip,1500-mile adventure. I must confess I haven’t thought about this tiny ice-cream business until a few days ago, when in my old age, I realized the importance of this little business experience.

In late August In 1966, I was discharged from the U.S. Navy at Treasure Island near San Francisco. Just days later, I arrived at the University of Kansas in Lawrence to begin my studies in Mechanical Engineering. The Navy had provided me a good technical education and the opportunity for responsibility and leadership. I was also coached and encouraged by the engineering officers during my time aboard ship. But four years had passed since my high school graduation, and frankly, I was worried about performing at the university level. My fears were soon confirmed when I earned an F on my first theme assignment in English, a required class. Fortunately, I learned how to write a little, I passed the class, and by the end of my first semester I settled into the busy, but manageable college routine.

Making Connections

Looking back on my 4 ½ years at KU, I recognize several important touchstones that shaped my early career. During my freshman year at KU, I was awarded a 4-year partial scholarship by Black & Veatch, a large Kansas City engineering firm. The scholarship included a paid summer internship that helped with my school expenses. I learned valuable drafting skills and was very grateful, but not inspired.

Professor Bill Barr taught a mechanical engineering class at KU for developing young entrepreneurs. I was selected to work in Barr’s program that provided part-time income doing technical searches for area businesses. This experience honed my researching and writing skills, and best of all, I was being paid to learn. Through Professor Barr, I had the good fortune to meet Gene Burnett, president of Burnett Instrument Company, a small Lawrence, KS manufacturer of medical equipment. Mr. Burnett offered me a summer job after my sophomore year at KU in 1968. I helped design new injection molded products for the company. During this time Burnett had perhaps 15 employees.

Working in Burnett’s small manufacturing firm, I got a close look at nearly everything they were doing. They made surgical instruments, most of which Burnett designed himself. Burnett held several patents and he designed and manufactured the first electric skin grafting machine. He also designed several disposable plastic medical instruments. Other products included an electric cast saw, a therapy device for hand injuries, and a dental device. Over the summer I was introduced to injection molding, and I designed two new disposable plastic parts for Burnett. This led to other important contacts, including Burnett’s patent lawyer, area molders and mold builders. Best of all, I had the chance to observe Mr. Burnett in action. He was dignified, creative, and above all, an ethical businessman. Without any intention Mr. Burnett was a mentor who showed me the inner workings of a successful small manufacturing business. These experiences really excited me, and I realized I would like to someday start my own business. I can say with certainty that Mr. Burnett was the most important influence in my life. Privately, I thought of him as a father figure. He remained a valued friend and advisor until late in his life.

Dave Carson was a mechanical engineering classmate of mine at KU and we became close friends. We both had the entrepreneurial itch, and in our junior year Carson and I decided to start a business doing library research for clients. We called it “Carson & Burger Technical Services”. We ordered business cards and knocked on some doors in our local area. Burnett Instrument Company was one of the first businesses we approached. Mr. Burnett suggested we contact Jim Schwartzburg, founder of Packer Plastics, an injection molding company that had recently started up in Lawrence, KS. in 1968.

Dave and I met with Jim and found him to be a friendly and likeable man. Jim gave us a plant tour, and we noticed the large volume of lids being produced and the amount of labor required to orient and stack the lids. It was clear that they needed a better way to orient and stack the Cool Whip lids. Dave and I asked for a chance to work on this problem and offer an improved way to orient the lids. Jim agreed to fund a little experimentation and Dave and I got to work. We developed a simple orienting method that led to a successful design for automatically stacking the lids.

Dave and I developed a successful lid orienting and stacking system that led to a Carson & Burger Patent and the startup of a business in 1970, making automation equipment for stacking lids as well as containers. We built and sold our first successful lid-stacking machine to Sunset Plastics in Kansas City in 1970 just before our graduation from KU.

At this point Dave and I were fully committed to the idea of being in business together, but we had not given much thought to the real “nuts and bolts” of running a business. We were simply having fun creating automation equipment that met a need in the packaging industry. Our first machine, crude as it was, proved the need for this kind of stacking automation. We were determined to improve our equipment and find other customers, but we really needed some experienced help.

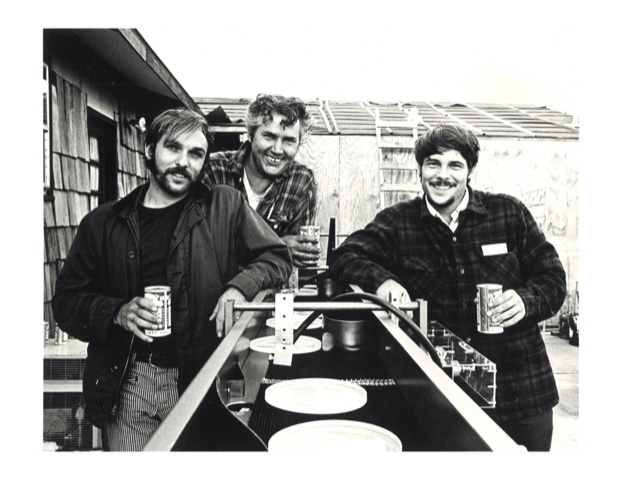

Gene Burnett, understanding our situation, introduced us to Jon Weekly in the summer of 1970, thinking that Jon might be able to help Dave and me. Jon was a few years older, and he had both construction and factory experience. Jon helped us build our stacker and we agreed to pay him by the hour for his work. But in short order, we ran out of money and were unable to pay Jon. Our solution was to offer Jon a one third ownership stake in the company. He accepted, and we became Carson, Burger & Weekly, later known as CBW, Inc. Jon made a huge difference for us, bringing his natural gift for leading people, useful work experience, and much needed maturity and wisdom.

I think back today on how naïve and unprotected we all were as our business grew. We were having success at manufacturing and selling and our equipment, but as we grew, we failed to recognize the risk of being in a three-way partnership. Any two partners could force the third partner out of the business without cause.

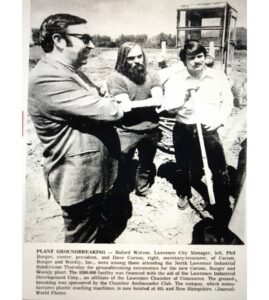

Dave and I, as fresh KU Engineering grads, handled equipment design, sales, and early on, even some hands-on manufacturing. We were in many ways unprepared, but customers bought our equipment, despite our inexperience because it worked and solved a problem. Some early customers were Sunset Plastics, Plastic Enterprises, Packer Plastics, Kraft Foods, and Amoco Molding in Southern California. In 1971 we moved into a larger space in the basement of the old Lawrence Paper Company building along the Kansas River. As we continued to grow, we broke ground on a new 20,000 sq. ft. building in North Lawrence on June 1, 1973.

Funds for the building and additional manufacturing equipment came from an SBA loan. We were just starting construction on the new building when sales went flat. We were strapped for cash so Jon became the general contractor for the building, allowing contractor fees to flow into CBW coffers. Dave recalls, “We may not have survived, but for Jon’s ability to build that building himself.”

These were exciting times for us young, inexperienced entrepreneurs, but trouble was on the horizon. Two years after moving into the North Lawrence building, we encountered a steep decline in sales. Our top-heavy three-way partnership could not be sustained. This was a valuable lesson about business ownership, and specifically, a partnership. A partner is just an employee of the other partners unless he owns more than 50% o

f the business. This was a valuable lesson for each of us as we each went our separate ways.

Jon had a background in construction and started a successful commercial construction business in Lawrence. My experience developing the early lid stackers led to a 3-year hitch at Sunset Plastics in Lenexa, KS. as plant manager.

Dave Carson moved CBW to Ft. Collins, Colorado in 1989, where he currently resides. He sold CBW Automation to a European Automation firm in 2012.

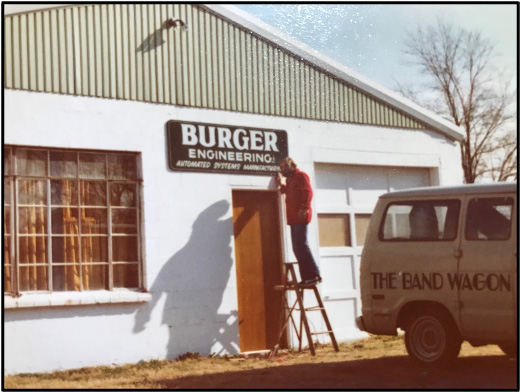

These are some experiences and lessons that led to my founding of Burger Engineering in March 1978. For better or worse, I was eager to be in control of my own destiny, like with the small ice-cream business of my youth.

Burger Engineering, Inc. started as an army of one, in a rented 2000 sq.ft. building in Olathe, KS. My equipment list included a six-foot drafting table, a 16” Southbend lathe, a Bridgeport Milling machine, an air compressor, and an antique cutoff saw, all bought with borrowed money. I was thrilled with my independence! I had skills. I just needed to knock on some doors!

THE END! For now.

FEB. 26, 2023